5g industrial router technology drives industrial digital transformation with ultra-fast, reliable, and secure connectivity. Manufacturers, energy providers, and logistics companies now use 5g routers to enable real-time control and predictive analytics. The industrial 5g router market expands rapidly as North America leads in deployment and Asia-Pacific shows the fastest growth. Market value is projected to rise from USD 2.1 billion in 2024 to USD 6.5 billion by 2033. Innovations in 5g, such as network slicing and edge computing, support industrial automation and boost efficiency across sectors.

- 5g industrial router adoption accelerates in manufacturing, energy, transportation, and logistics.

- The industrial 5g router market benefits from Industry 4.0, private 5g networks, and rising demand for real-time data.

- 5g technology enables new industrial automation capabilities and supports advanced security features.

Wichtigste Erkenntnisse

- 5G industrial routers deliver ultra-fast, reliable, and secure connectivity that enables real-time control and automation in manufacturing, energy, logistics, and smart cities.

- Advanced features like low latency, massive device connectivity, and network slicing allow industries to run multiple applications smoothly and safely on the same network.

- Integration with edge computing and AI supports faster decision-making, predictive maintenance, and efficient asset management, reducing downtime and costs.

- Rugged designs and strong security measures ensure 5G routers operate reliably in harsh industrial environments while protecting sensitive data.

- Leading brands and expanding private 5G networks drive innovation and scalability, helping industries improve productivity and prepare for a connected future.

5g Industrial Router: Key Technological Advancements

Ultra-Fast Data Speeds

5g industrial routers deliver a leap in speed compared to previous generations. These routers enable rapid transmission of large volumes of data, which is essential for real-time monitoring and control in industrial settings. In manufacturing facilities, routers like those from Teltonika can achieve download speeds up to 3.4 Gbps. PUSR industrial routers reach up to 2.5 Gbps for downloads and 900 Mbps for uploads. These speeds allow factories to handle high-resolution video streams, sensor data, and analytics without delay.

| Marke | Maximum Download Speed | Maximum Upload Speed | Application Context |

|---|---|---|---|

| Teltonika | Up to 3.4 Gbps | K.A. | Real-time data transmission in manufacturing |

| PUSR | Bis zu 2,5 Gbit/s | Up to 900 Mbps | Global industrial 5g routers |

| Cisco | 10-20 Gbps (theoretical) | K.A. | Theoretical maximum, not specific to industrial routers |

5g network slicing enables these routers to dedicate bandwidth for critical applications, ensuring uninterrupted performance even during peak usage. This capability supports the growing demand for high-speed connectivity in smart factories and automated warehouses.

Anmerkung: Enhanced anti-interference features in 5g routers improve signal stability, even in environments with heavy machinery and electromagnetic noise.

Low Latency for Real-Time Control

Low latency stands as a defining feature of 5g technology. In industrial automation, every millisecond counts. 5g industrial routers achieve millisecond-level latency, which allows for immediate response in applications such as remote-controlled machinery, robotics, and autonomous vehicles. In contrast, 4G routers typically experience latency between 20 and 50 milliseconds, which can cause delays and reduce efficiency.

| Merkmal | 5G Industrial Router | 4G LTE Industrial Router |

|---|---|---|

| Latenzzeit | Millisecond-level, extremely low | 20-50 ms under ideal conditions |

| Transmission Speed | Gbps-level throughput | Tens to hundreds of Mbps |

| Verlässlichkeit | High, reduces production risks | Less reliable, higher latency |

| Device Connection Density | Supports many devices | Limited capacity |

| Automation Impact | Enables real-time control | May cause lag in control instructions |

5g network slicing further enhances low latency by allocating dedicated network resources to time-sensitive tasks. This ensures that critical commands and sensor data reach their destination without delay. The result is safer, more efficient, and more intelligent industrial operations.

Massive Device Connectivity

Modern factories and warehouses rely on thousands of connected devices. 5g industrial routers support massive device connectivity, far surpassing the limits of previous technologies. For example, the Peplink MAX BR2 Pro 5G Cellular Router can connect up to 150 devices simultaneously in a single factory setting. This level of connectivity is vital for supporting a dense network of sensors, machines, and IoT devices.

- 5g network slicing allows for the creation of multiple virtual networks, each tailored to specific device groups or applications.

- Routers support multiple industrial Ethernet protocols, such as EtherNet/IP, PROFINET, and Modbus TCP, ensuring compatibility with existing equipment.

- Rugged designs with IP67 protection make these routers suitable for harsh industrial environments.

5g technological innovations, such as RBMS (Routing Behind Mobile Station), enable seamless integration into existing networks without changing IP addresses. This simplifies upgrades and reduces downtime. Enhanced security features, including advanced encryption and authentication, protect data and ensure only authorized devices connect to the network.

Tipp: Integration with edge computing allows 5g routers to process data locally, reducing the need to send information to distant servers. This further improves low latency and supports real-time analytics.

Network Slicing for Customization

5g network slicing stands out as one of the most important technological innovations in industrial automation. This technology allows a single 5g network to split into multiple virtual networks, or “slices,” each designed for a specific purpose. Each slice can have its own settings for bandwidth, latency, and security. This means factories, energy plants, and logistics centers can run different applications on the same physical network without interference.

- 5g network slicing supports different industrial applications by allocating dedicated slices with specific connectivity parameters, avoiding interference.

- In industrial IoT and SCADA systems, dedicated slices prioritize uptime, low latency, and reliable connectivity for sensors and control systems in harsh environments.

- Remote industrial monitoring benefits from slices that ensure secure, reliable 24/7 data transmission from isolated assets.

- By isolating critical industrial functions on dedicated slices, network congestion and interference from less critical traffic are minimized, ensuring peak operational performance.

5g network slicing uses software-defined networking (SDN) and network function virtualization (NFV) to create and manage these slices on demand. Each slice can be set up independently across the radio, transport, and core network layers. For example, a factory can use one slice for high-bandwidth video streams from cameras and another for low-latency robotic commands. This flexibility allows companies to optimize resources, reduce costs, and launch new services quickly.

Tipp: Logical isolation of slices also improves security, as each slice can have its own access controls and policies.

Integration with edge computing further enhances 5g network slicing by supporting real-time data processing for latency-sensitive applications. Companies can scale and modify slices as their needs change, making 5g network slicing a powerful tool for modern industrial environments.

Verbesserte Sicherheitsmerkmale

Security remains a top priority in industrial automation. 5g industrial routers introduce advanced security features to protect against cyber threats. These routers use integrity protection and encryption for both control and user data, making it difficult for attackers to intercept or manipulate information.

- 5g network slicing enables segmentation of industrial networks into isolated slices with distinct security policies, improving control and mitigating risks of unauthorized access or resource draining.

- IPSec ESP protocol provides confidentiality, integrity, and replay protection on internal 5g interfaces, with IKEv2 for certificate-based authentication.

- SUPI encryption protects subscriber identities, preventing tracking and privacy attacks.

- Multi-level authentication schemes include primary authentication, secondary authentication for external networks, and slice-specific authentication for segmented access control.

- Lightweight cryptographic algorithms, such as AES-GCM and BP-MAC, reduce latency and support devices with limited resources.

- Optional controls, like gNb certificates and 256-bit encryption, add extra layers of protection.

- 5g’s wireless interface uses encryption and integrity protection to defend against eavesdropping and manipulation.

- Nano-segmentation techniques allow per-device verification of packet origin and flow authorization, strengthening network security.

These features ensure that only authorized devices and users can access sensitive industrial systems. 5g network slicing also helps by keeping critical operations separate from less secure traffic. This layered approach to security protects industrial assets and keeps operations running smoothly.

Multi-Access Edge Computing Integration

Multi-access edge computing (MEC) works hand-in-hand with 5g to boost automation and efficiency in industrial settings. By processing data closer to where it is generated, MEC reduces the need to send information to distant cloud servers. This leads to faster decision-making and lower latency, which is vital for real-time control and predictive maintenance.

| Aspekt | Explanation |

|---|---|

| Real-time process control & predictive maintenance | MEC enables immediate decision-making on the factory floor, reducing operational downtime and supporting automation. |

| Latency reduction | Processing data closer to the source reduces dependency on centralized cloud, lowering latency critical for automation. |

| Support for advanced technologies | MEC facilitates robotics, AI-driven quality control, and digital twins without relying on remote cloud infrastructure. |

| Dynamic resource allocation & orchestration | Software solutions at the edge manage distributed infrastructure in real time, enhancing efficiency and minimizing latency. |

| 5g network synergy | 5g’s high bandwidth and low latency accelerate MEC deployments, offloading network traffic and enabling time-sensitive services. |

| Industrial use cases | Manufacturing, monitoring, maintenance, and autonomous systems benefit from MEC and 5g integration for improved operational agility. |

| Robust connectivity via 5g industrial routers | Ensures reliable network management and connectivity, optimizing edge computing environments. |

| Enterprise adoption | Large enterprises use MEC to handle complex workloads across dispersed locations, improving decision speed and reducing network congestion. |

| Wireless and wired MEC | Wireless MEC supports flexible, scalable environments; wired MEC ensures stable, low-latency connections for critical applications. |

5g network slicing enhances MEC by allowing each application to use a dedicated slice with the right performance and security settings. This combination supports robotics, AI, and digital twins, helping companies achieve smarter, more responsive operations. With robust connectivity from a 5g industrial router, businesses can manage their networks efficiently and keep up with the demands of modern automation.

5g Industrial Router Applications in Automation

Manufacturing Automation and Robotics

5g industrial routers have become essential in modern manufacturing environments. They provide the backbone for real-time data exchange between machines, sensors, and control systems. This connectivity supports smart factory solutions by enabling precise control of advanced robotics. For example, robots can assemble micro-components or inspect products with high accuracy because of 5g’s ultra-low latency.

Manufacturers use 5g routers to connect programmable logic controllers (PLCs), robots, and sensors. This setup allows for real-time data collection and process optimization. Autonomous mobile robots (AMRs) rely on 5g to navigate factory floors, coordinate tasks, and optimize routes instantly. Operators can monitor and control robotic systems remotely, which improves safety in hazardous environments.

5g routers support secure, reliable data transmission. This is critical for AI-driven manufacturing, where data privacy and smooth operation matter most.

The integration of 5g with artificial intelligence enables predictive maintenance. By analyzing sensor data in real time, companies can reduce downtime and extend equipment life. 5g also allows for seamless machine-to-machine communication, making it easy to reconfigure production lines and scale operations.

| Application Aspect | Beschreibung |

|---|---|

| Equipment Interconnection & Data Collection | 5g routers connect sensors, controllers, and robots, enabling real-time data collection and transmission to cloud or local servers. |

| Remote Monitoring & Maintenance | Technicians monitor equipment remotely, respond quickly to failures, and perform predictive maintenance. |

| IoT Integration & Intelligent Upgrade | 5g routers act as key nodes for device interconnection in IoT platforms, enhancing automation and enabling AI-driven management. |

| Production Efficiency Improvement | Real-time data exchange allows precise control of production processes, increasing efficiency and reducing labor costs. |

| Data Security Enhancement | Built-in security features protect data privacy and prevent leaks. |

| Adaptation to Harsh Environments | High stability and anti-interference capabilities allow operation in extreme industrial conditions. |

These key applications help manufacturers improve efficiency, reduce labor costs, and maintain stable operations even in challenging environments.

Energy Sector: Smart Grids and Remote Monitoring

The energy sector depends on 5g industrial routers to modernize infrastructure and improve operational efficiency. These routers enable real-time monitoring and control of energy production and distribution systems, including renewable sources like wind and solar. Grid operators use 5g to balance supply and demand with precision, which enhances grid stability and efficiency.

5g’s low latency and high reliability are vital for integrating renewable energy sources. Operators can monitor and maintain energy infrastructure remotely, reducing the need for on-site personnel and lowering operational costs. Predictive maintenance becomes possible by analyzing equipment data in real time, which helps prevent failures and reduces downtime.

- 5g routers support large data volumes, which is essential for smart grid management and advanced energy systems.

- Real-time monitoring ensures quick response to faults or changes in energy demand.

- Remote management capabilities allow for efficient scheduling and maintenance of assets in wind farms, hydropower stations, and solar fields.

5g technology contributes to a more resilient, efficient, and sustainable energy sector by supporting reliable communications in harsh environments.

These industrial applications help energy companies achieve better performance, reduce costs, and support the transition to cleaner energy sources.

Transportation and Logistics Optimization

Transportation and logistics companies rely on 5g industrial routers to optimize operations and improve service quality. These routers provide always-on, high-speed connectivity for real-time vehicle tracking, performance monitoring, and dynamic route optimization. Fleet managers receive instant updates on vehicle location and status, which helps them make better decisions and improve delivery times.

5g routers enable real-time traffic and road condition updates. Fleet managers can adjust routes to avoid delays caused by congestion, accidents, or weather. Continuous communication between vehicles and dispatch centers allows for instant route changes and schedule adjustments.

- Enhanced GPS accuracy and fast data transfer provide precise vehicle location updates.

- Smarter routing reduces idling and detours, which lowers fuel costs and environmental impact.

- Real-time guidance and hazard alerts improve driver safety and help meet delivery deadlines.

- Security features like VPN, encryption, and firewalls protect sensitive fleet and delivery information.

- Automatic fallback to 4G or 3G networks ensures uninterrupted tracking and communication, even in remote areas.

5g technology transforms logistics by enabling instant communication among supply chain partners, supporting smarter decision-making and efficient operations.

These advancements in industrial automation allow logistics companies to maximize output, reduce costs, and deliver better service to customers.

Environmental Monitoring and Smart Cities

5G industrial routers play a vital role in building smarter, safer, and more sustainable cities. These advanced routers create fast, encrypted data channels that connect a wide range of devices, from environmental sensors to IoT edge systems. City managers use these connections to monitor air quality, water purity, and noise levels in real time. This immediate access to environmental data helps leaders make informed decisions and respond quickly to changing conditions.

- 5G industrial routers support low-latency and high-reliability communication. This feature allows smart city systems to react instantly to emergencies, such as sudden spikes in pollution or unexpected weather events.

- The routers operate reliably in harsh environments. Their rugged designs resist extreme temperatures, moisture, lightning, and electromagnetic interference, ensuring stable performance across city infrastructure.

- High data throughput and multiple industrial interfaces allow these routers to connect thousands of devices. This capability supports large-scale data collection and management for smart city projects.

Environmental protection departments rely on 5G routers to gather and transmit data from sensors placed throughout the city. These sensors track air and water quality, as well as noise pollution. The routers send this information to central systems, where experts analyze trends and detect problems. When air quality drops below safe levels, the system can issue early warnings to protect public health.

Real-time data collection and transmission improve the accuracy and timeliness of environmental monitoring. This supports better policy decisions and helps cities respond to environmental challenges.

Long-term storage and analysis of environmental data also support urban planning and pollution control. City planners use this information to design cleaner, healthier neighborhoods. 5G routers enable other smart city features, such as smart energy management, intelligent transportation, and emergency rescue operations. Their technical strengths—high speed, low latency, large capacity, and strong environmental adaptability—ensure reliable operation of critical infrastructure.

How 5g Industrial Routers Drive Industrial Automation

Remote Equipment Control and Monitoring

5g industrial routers transform remote equipment control and monitoring in modern factories. These routers deliver high-speed, low-latency connections that support real-time data transmission between machines and control centers. Devices such as PLCs, sensors, and industrial cameras connect seamlessly, enabling operators to monitor and manage equipment from any location. The IR2005G router, for example, provides up to 3.4 Gbps speeds and automatic failover between Ethernet, WiFi, and cellular networks. This ensures uninterrupted service, even in harsh environments. Secure communication features like encryption, VPN tunnels, and firewalls protect sensitive data. Device management servers allow remote diagnostics, software updates, and configuration changes, reducing the need for on-site visits. These capabilities improve production efficiency and data reliability while minimizing downtime.

Predictive Maintenance and AI Integration

5g industrial routers enable predictive maintenance by supporting AI-driven analytics and real-time data exchange. AI systems analyze sensor data to detect patterns and predict equipment failures before they occur. This proactive approach prevents costly breakdowns and reduces unplanned downtime. Machine learning algorithms identify anomalies in machinery performance, allowing maintenance teams to address issues early. AI-powered robots communicate over 5g networks to coordinate complex tasks and optimize production lines. Continuous monitoring and rapid data processing enhance decision-making and streamline operations. As a result, companies experience smoother workflows, improved reliability, and significant cost savings.

Predictive maintenance powered by 5g and AI leads to fewer disruptions and longer equipment lifespans.

Intelligent Asset Management

5g industrial routers play a key role in intelligent asset management for large-scale operations. These routers provide secure, scalable connectivity at the edge, supporting both mobile and fixed assets. Modular hardware designs allow for easy upgrades, extending device lifecycles. Advanced security tools offer full visibility and threat detection, protecting assets from cyber risks. Built-in edge computing processes data locally, enabling real-time monitoring and application hosting. Support for multiple communication protocols ensures reliable operation across diverse environments. Features like dual SIM support, GNSS for asset tracking, and automated failover maintain continuous connectivity. Cloud-based management platforms enable centralized monitoring and remote control, improving operational efficiency and reducing costs.

Edge Computing Capabilities

5G industrial routers bring powerful edge computing capabilities to industrial automation. These routers process data locally, which reduces the need to send information to distant servers. This approach improves response times and helps factories make quick decisions. Companies can optimize workflows and adjust production in real time, even in harsh environments.

Key edge computing features of 5G industrial routers include:

- Real-time data collection and processing through multiple external interfaces

- Low latency and high-speed communication based on 5G networks

- Support for industrial protocols such as OPCUA and MODBUS

- Advanced security with SPI firewall, VPN traversal, access control, and encryption

- Network redundancy using wired, dual-mode 5G, and VRRP three-level link hot backup

- Rugged design for operation in extreme temperatures (-40~+80ºC)

- Flexible networking with dual SIM dual standby and multiple VPN protocols

- Integration with major IoT platforms, including Huawei, Ali, Telecom, and Mobile

- Remote operation and maintenance through cloud management platforms

- AI intelligence at the edge for real-time visual feedback and control

- Application in high-risk industries to improve safety and efficiency

| Networking Solution Type | Beschreibung | Industrial Application Example |

|---|---|---|

| 5G Point-to-Point Communication | Direct device-to-device connection enabling real-time data transmission with low latency | Robotic collaboration and AGV cluster scheduling |

| 5G End-to-End Networking | Large-scale IIoT network formation with comprehensive device interconnection and edge data processing | Smart ports with interconnected cranes and autonomous trucks |

| 5G and Optical Fiber Dual-Channel | Dual-channel network combining 5G and optical fiber for high reliability and failover | Smart grids ensuring continuous data transmission and real-time analysis |

5G industrial routers support AI and machine learning at the edge, which allows for immediate analysis and control. This capability increases production flexibility, operational efficiency, and safety. Companies benefit from robust, secure, and scalable solutions that meet the demands of modern industrial automation.

Unique Advantages of 5g Industrial Router Technology

Reliability and Uptime in Harsh Environments

5G industrial routers deliver unmatched reliability in the most demanding industrial settings. In oil and gas operations, these routers maintain secure communications in remote and hazardous locations. Their HazLoc Class 1 Div 2 certification prevents ignition in explosive atmospheres. Rugged enclosures withstand extreme temperatures, dust, water, and corrosive chemicals. Compliance with MIL-STD-810G and SAE J1455 standards ensures durability during mechanical shocks and constant vibration. Cisco’s Catalyst IR1100 and IR1800 Rugged Series routers offer modular and compact 5G connectivity for utilities, renewable energy, and manufacturing. These routers support extreme temperature ranges and space-constrained installations. Their design guarantees long device lifetimes and reliable network uptime. Continuous monitoring and control of remote assets become possible, which is critical for worker safety and operational efficiency.

| Merkmal | Nutzen Sie |

|---|---|

| HazLoc, MIL-STD-810G, IP ratings | Safe operation in hazardous conditions |

| Hardened, fire-resistant enclosure | Protection against fire and chemicals |

| Dual-SIM failover | Continuous uptime and high reliability |

| Remote management tools | Proactive monitoring and reduced downtime |

5G industrial routers use proprietary connection monitoring software and remote management tools to support high reliability and minimize downtime. Their reliability ensures uninterrupted connectivity, which is vital for industrial automation.

Scalability for Expanding Operations

Industrial automation demands scalable solutions. 5G industrial routers provide scalability for expanding operations through multiple interfaces, including Ethernet, serial ports, and Wi-Fi. These interfaces connect diverse devices such as PLCs, sensors, and robots. Support for various communication protocols, including 5G and 4G, allows adaptation to complex scenarios. Hardware module additions and software upgrades enable routers to handle explosive growth in industrial IoT devices. Dual-mode 4G/5G compatibility and future upgradeability ensure smooth transitions as technology evolves.

- Ultra-fast internet supports real-time data transmission in manufacturing, healthcare, and logistics.

- Cost-effective network expansion alternatives benefit remote areas where fiber-optic installation is expensive.

- IoT and smart technologies enable seamless operation of smart factories and automated systems.

- Hardware expansion allows for additional interfaces and storage.

- Security enhancements ensure safe data transmission.

In automobile manufacturing, upgrading to 5G routers increased transmission speeds from hundreds of Mbps to several Gbps. This improvement enabled smooth real-time video transmission and supported large-scale industrial intelligence development. Scalability remains a key advantage, allowing industries to grow without sacrificing reliability.

Advanced Security and Data Protection

Security and data protection are essential in industrial automation. 5G industrial routers offer advanced features that surpass previous technologies. Support for robust VPN protocols, including IPSEC, L2TP, PPTP, OpenVPN, GRE, and DMVPN, ensures secure connections. Modular hardware and software architecture allow customization of I/O interfaces. Compliance with industry-specific protocols, such as MQTT authentication, strengthens security. Dual 5G modules and dual SIM cards provide redundancy and reliability.

- Advanced encryption protocols like WPA3 deliver stronger security algorithms.

- Firewalls and packet filtering protect internal networks.

- Intrusion Detection and Prevention Systems (IDPS) monitor and mitigate threats in real time.

- Multi-Factor Authentication (MFA) adds extra verification layers.

- Secure boot processes ensure only trusted manufacturer software runs.

- Network slicing creates isolated virtual networks, enhancing security by segregating data streams.

Operating systems supporting advanced programming environments, such as Linux with Python and C++, enable tailored security implementations. Optional features like GPS/Beidou, timing synchronization, and power encryption/eSIM provide secure operations. These capabilities ensure high reliability and protect sensitive data in industrial environments.

Integration with Industrial IoT Platforms

5G industrial routers play a central role in connecting industrial IoT platforms. These routers provide high-speed, reliable connectivity that supports automation across manufacturing, energy, and transportation sectors. Companies use 5G routers to link machines, sensors, and control systems, creating a unified network for real-time data exchange.

Industrial IoT platforms rely on 5G routers for several key functions:

- Automation and robotics use 5G and IIoT platforms to streamline industrial processes and reduce labor costs.

- Edge computing processes data from connected IoT devices locally, sending actionable insights to operations centers. This improves real-time decision-making.

- Manufacturing facilities connect automated machinery and sensors to enhance efficiency, minimize downtime, and provide real-time analytics.

- Automotive companies optimize fleet management and automate parts inventory through connected systems.

- Energy and utility providers use IIoT for remote monitoring, predictive maintenance, and improved worker safety with sensors and wearable devices.

- 5G acts as a force multiplier for IIoT by delivering reliable, high-speed connectivity essential for these automation enhancements.

The Digi IX40 5G industrial router demonstrates how integration works in practice. It combines 5G connectivity with edge computing, allowing rapid processing and analysis of industrial asset data. This router connects multiple machines in demanding environments, optimizing the integration of operational technology with information technology. Centralized management through Digi Remote Manager® enables remote device management, automated network monitoring, configuration management, firmware updates, and troubleshooting. Digi Containers support hosting containerized IIoT applications at the edge, making it easier to deploy predictive maintenance, asset monitoring, machine learning, and advanced robotics.

Companies benefit from reduced complexity and improved real-time decision-making. Integration with industrial IoT platforms allows organizations to scale operations, increase efficiency, and respond quickly to changing conditions.

| IIoT Platform Benefit | 5G Router Contribution |

|---|---|

| Real-time analytics | High-speed data transmission |

| Predictive maintenance | Edge computing and remote access |

| Asset monitoring | Secure, scalable connectivity |

| Automation | Reliable, low-latency networks |

5G industrial routers enable seamless integration with IIoT platforms, supporting smarter, safer, and more efficient industrial automation.

Industrial 5g Router Market: Leading Products and Brands

The industrial 5g router market continues to expand as industries demand robust, secure, and high-speed connectivity. Leading brands deliver advanced solutions that address the needs of automation, scalability, and security. This section explores three prominent products shaping the industrial 5g router market.

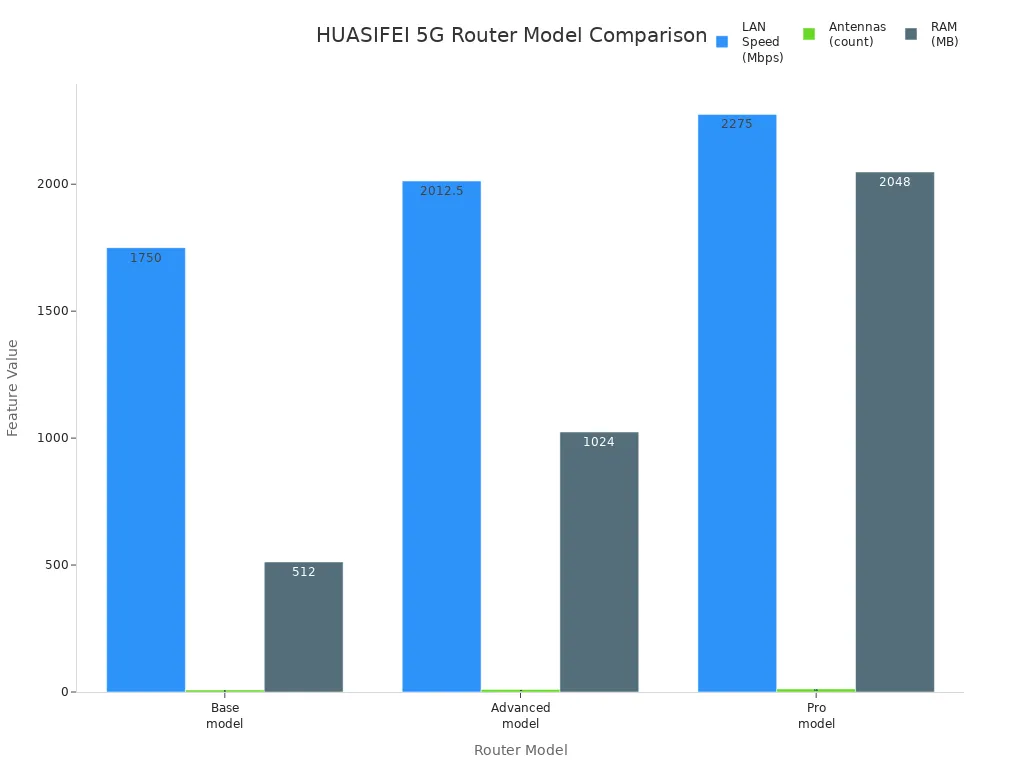

HUASIFEI 5G Industrial Routers

HUASIFEI stands out in the industrial 5g router market with its Dual Band 4G 5G Router series. These routers support both 4G and 5G networks, offering Wi-Fi 6 connectivity and dual-band speeds up to 2275Mbps. The industrial-grade aluminum body ensures durability and effective heat dissipation in harsh environments. Multiple external antennas provide up to 50% wider coverage, supporting stable connections in large facilities. Security features include a firewall, QoS traffic management, and WPA3 encryption. The routers offer USB 3.0, LAN ports (including 2.5G LAN), and flexible SIM options. CE and RoHS certifications guarantee compliance with international standards.

| Modell | LAN Speed | Antennen | SIM-Optionen | RAM | Anwendungsfall |

|---|---|---|---|---|---|

| Base | 1750Mbps | 8 | Single SIM | 512MB | Standard industrial automation |

| Fortgeschrittene | 2012.5Mbps | 10 | Dual-SIM | 1GB | Enhanced connectivity needs |

| Pro | 2275Mbps | 12 | Dual SIM + eSIM | 2GB | Demanding industrial environments |

The WS988 4G industrial router from HUASIFEI also supports stable internet access in extreme temperatures, with plug-and-play convenience and remote management. These features position HUASIFEI as a key player in the industrial 5g router market.

Anybus Wireless Bolt 5G Router

Anybus Wireless Bolt 5G Router holds a strong position in the industrial 5g router market. This device supports multiple industrial Ethernet protocols, including PROFINET, EtherNet/IP, and Modbus TCP. The router uses 3GPP Release 16 5G technology for ultra-low latency and reliable communication. Its rugged design with an IP66 rating withstands harsh environments. Built-in antennas and easy mounting options simplify installation. Power options include Power over Ethernet and a 24 VDC connector.

- Seamless integration with existing controllers without programming changes

- Works with Anybus Tunnel Gateway for real-time, deterministic communication

- Siemens-certified and Ericsson-verified for interoperability

- Web-based configuration interface for setup and monitoring

- Suitable for robotics, AGVs, HMIs, machine-to-cloud communication, and remote surveillance

These features make the Anybus Wireless Bolt 5G Router a preferred choice in the industrial 5g router market for Industry 4.0 and IIoT applications.

Nokia Industrial 5G Fieldrouters

Nokia’s Industrial 5G Fieldrouters play a significant role in the industrial 5g router market. These routers deliver reliable 5G connectivity for mission-critical industrial automation. Nokia designs its fieldrouters for deployment in factories, energy plants, and transportation hubs. The routers support high-speed data transfer, low latency, and robust security. Industrial-grade enclosures protect against dust, moisture, and vibration. Nokia’s routers integrate with private 5G networks, enabling secure and scalable operations. Centralized management tools allow remote monitoring and configuration. These capabilities help industries achieve seamless automation and efficient asset management.

The industrial 5g router market benefits from these leading brands, each offering specialized features for different industrial needs. As the industrial 5g router market grows, these products set the standard for performance, reliability, and innovation.

Other Notable Brands: Cisco, Siemens, Advantech

The industrial 5g router market features several leading brands that deliver robust solutions for industrial automation. Cisco, Siemens, and Advantech have established themselves as key players in the industrial 5g router market. Their products address the need for high-speed, reliable, and secure connectivity in demanding environments.

Cisco designs routers for the industrial 5g router market with ruggedized hardware. These devices withstand extreme temperatures, dust, and vibration. Cisco routers support both public and private 5G networks, making them suitable for diverse industrial settings. Integration with IIoT platforms allows seamless communication between machines and sensors. Cisco also incorporates advanced security features to protect critical infrastructure in the industrial 5g router market.

Siemens focuses on connectivity and automation in the industrial 5g router market. Their routers feature durable enclosures and support for edge computing. Siemens routers process data locally, enabling real-time decision-making on the factory floor. These devices integrate with automation systems and IIoT networks, helping companies optimize operations. Siemens emphasizes reliability and uptime in the industrial 5g router market.

Advantech offers solutions tailored for the industrial 5g router market. Their routers feature rugged designs and flexible mounting options. Advantech supports integration with IIoT and automation platforms, allowing for scalable deployments. Edge computing capabilities enable rapid data processing and analytics. Advantech includes AI-powered network management tools to enhance reliability and security in the industrial 5g router market.

The industrial 5g router market continues to grow as companies seek advanced connectivity for automation and data protection. Cisco, Siemens, and Advantech remain at the forefront, delivering solutions that meet the evolving needs of industrial environments.

| Marke | Key Features in the Industrial 5g Router Market |

|---|---|

| Cisco | Rugged hardware, IIoT integration, advanced security |

| Siemens | Edge computing, automation support, reliability |

| Advantech | Flexible design, AI-powered management, scalability |

The industrial 5g router market benefits from these brands’ commitment to innovation and quality. Their routers help industries achieve smarter, safer, and more efficient operations.

The Future of 5g in Industrial Automation

Trends in AI and Machine Learning Integration

AI and machine learning are shaping the next wave of industrial automation. Companies now use AI to select the best signal paths in real time, improving how devices connect and communicate. Massive MIMO technology, powered by machine learning, adjusts antenna settings to boost coverage and manage interference. AI also helps with 5g network slicing, allowing dynamic resource allocation and predictive maintenance. These innovations support low-latency decision-making and large-scale data analysis at the network edge.

- AI platforms combine machine learning, deep learning, and analytics for end-to-end automation.

- Edge AI processes data locally, reducing latency and improving privacy.

- AI-driven automation increases network reliability and capacity.

- Industry-specific AI solutions address needs in manufacturing, smart cities, and healthcare.

AI-powered security solutions now detect threats in real time and respond automatically, making industrial networks safer.

Expansion of Private 5g Networks

Private 5g networks are changing how industries approach automation. Automotive and manufacturing leaders use private networks to connect machines, sensors, and workers. For example, Ford’s Rouge complex and Mercedes-Benz’s Factory 56 use private 5g to track assets, guide vehicles, and support predictive maintenance. These networks provide low latency, high reliability, and strong security. Companies can reduce their reliance on wired infrastructure, making it easier to adapt to new market demands.

- Private 5g supports mobile asset automation, such as automated guided vehicles.

- Real-time visibility and secure data control improve efficiency and safety.

- Enhanced digital transformation becomes possible with robust wireless connectivity.

Evolving Standards and Interoperability

The evolution of standards and interoperability remains a key focus for the future. Differences in technical standards, business models, and regulations create challenges for seamless integration. Operators, vendors, and regulators must work together to solve these issues. The move to Standalone 5g networks enables advanced features like network slicing, low-latency services, and differentiated quality of service. New 5g-Advanced standards promise better energy efficiency, AI-native automation, and improved positioning.

- Integration with non-terrestrial networks, such as satellites, expands coverage to remote areas.

- Energy-efficient designs and renewable energy use help reduce operational costs.

- Real-world deployments face hurdles with infrastructure investment and cybersecurity.

As these innovations progress, industries will benefit from greater flexibility, security, and scalability in their automation strategies.

5g technology acts as a catalyst for smarter and safer industrial automation. Companies now achieve higher productivity and flexibility by combining AI, edge computing, and real-time data processing. Manufacturing leads this shift, with North America at the forefront. As market growth continues, industries will see even greater efficiency and security. The future promises fully connected operations, where advanced routers and intelligent systems work together for optimized results.

Industrial automation stands ready for a new era of innovation and connectivity.

FAQ

What is a 5G industrial router?

A 5G industrial router connects machines, sensors, and control systems using 5G networks. It provides fast, reliable, and secure data transmission in factories, energy plants, and other industrial environments.

How does a 5G industrial router improve automation?

A 5G industrial router enables real-time data exchange and remote control. It supports predictive maintenance, asset tracking, and edge computing. These features help companies automate processes and increase efficiency.

Are 5G industrial routers secure?

Yes. 5G industrial routers use advanced encryption, firewalls, and network segmentation. These security features protect sensitive data and prevent unauthorized access.

Can 5G industrial routers work in harsh environments?

Yes. Many 5G industrial routers have rugged designs. They resist extreme temperatures, dust, moisture, and vibration. This durability ensures reliable operation in challenging industrial settings.